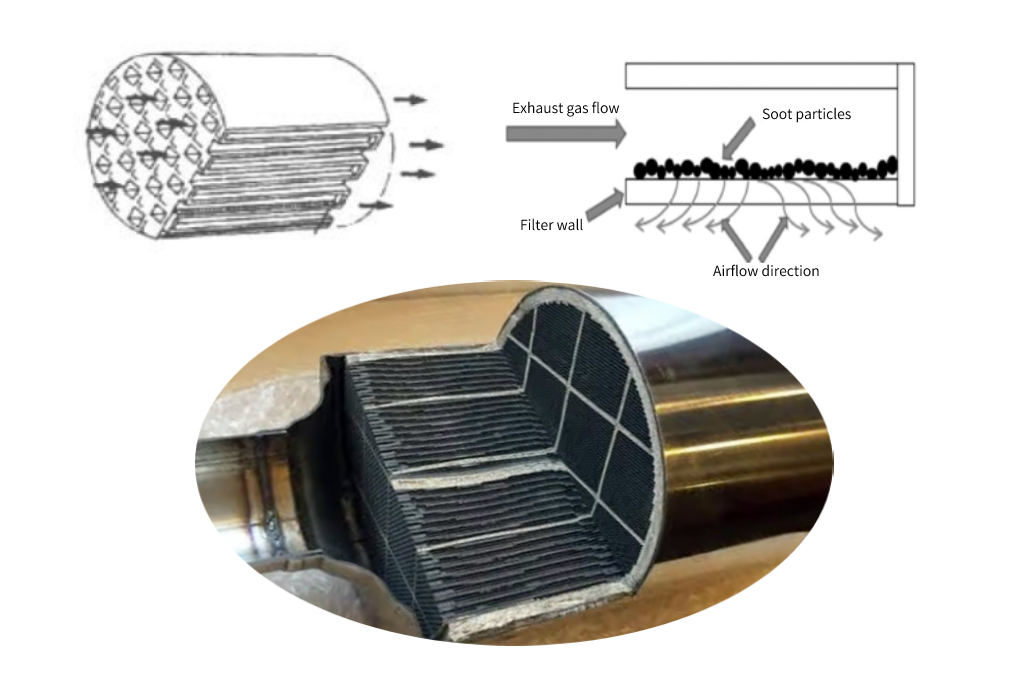

SIC DPF Honeycomb Ceramic Diesel Particulate Filter

Model Number:BS-SD

Place of Origin:Pingxiang,China

Keywords:sic dpf,sic diesel particulate filter,catalyst substrate

SiC Diesel particulate filter effectively remove particles and fumes from diesel engine exhaust emission. Its efficiency for carbon particulates filtration is more than 90%. So reduce the pollution to the enviroment. It would be a great help to solve theproblem of air pollution.

INQUIRE NOW

INQUIRE NOW

Contact us

86 (0) 799 6699600 / 0086 15179934828

jenny@bestpacking.cn

The particulate of emission is captured inside thin gas hole or entrance. As it lasts, the cumulated layer become thick, and pressure loss increase. To ensure the performance of engine, when pressure loss reaches some value, it is a must to recycle the filter. The recycle is making the particulate burning, by raising the gas temperature of filter.

Specification

Item

Units

Technical Index

Sic content

%

>90

Cell density

CPSI

200

Wall thickness

mm

0.35-0.41

Cell length

mm

1.2-1.45

Apparent porosity

%

42-60

Median pore size

m

12-20

Transverse compression strength

Mpa

>2.3

Vertical compression strength

Mpa

10-18

Coefficient of thermal expansion (40-800ºC)

10-6 /ºC

4.3-4.4

Thermal Conductivity (500ºC)

W/mK

14-22

Capture rate

%

>95

Bulk density

Kg/L

0.8

Filter area

m²/L

0.75

Softening temperature

ºC

1400

Size

CPSI

Volume(L)

φ118*152.4

100/200

1.67

φ118*254

100/200

2.78

φ127*152.4

100/200

1.93

φ127*180

100/200

2.3

φ127*254

100/200

3.22

φ144*152.4

100/200

2.49

φ144*203

100/200

3.31

φ144*254

100/200

4.44

φ144*305

100/200

4.97

φ190*152.4

100/200

4.32

φ190*203

100/200

5.76

φ190*305

100/200

8.65

φ240*240

100/200

10.9

φ240*305

100/200

13.8

φ250*305

100/200

14.97

φ267*254

100/200

14.22

φ267*267

100/200

14.95

φ267*305

100/200

17.07

φ286*305

100/200

19.6

φ286*355

100/200

22.8

φ305*305

100/200

22.28

φ330*381

100/200

32.59

Advantage

1. High filtration efficiency, high strength, strong resistance to thermal shock and mechanical vibration;

2. I have superior heat, corrosion resistance, and thermal conductivity;

3. The pore structure of SIC has better adjustability,

Filter materials with higher porosity and more uniform pore size distribution can be prepared;

After the airflow enters the DPF, due to the blockage of the outlet, the airflow flows out from the inner wall, forming a silicon carbide DPF carrier, which traps carbon smoke inside the DPF. The lifting mechanism of the silicon carbide DPF carrier plays a role in collecting carbon smoke, with a purification efficiency of over 90%. Finally, the collected carbon smoke is removed through regeneration and oxygenation combustion.

GENERAL ENQUIRY

Simply fill in the form below and we'll be in contact with you in 8 hours

Wechat

Wechat Skype

Skype Trade

Trade