Choose the right chemical packing reduce cost

2020-05-29

Commonly used fillers can also use coke, activated carbon, porcelain rings, metal loops, plastic wire mesh, etc. The separation efficiency of this separator increases with the increase of the surface area of the filler. The specific surface area of the stainless steel wire mesh with a diameter of 0.1 to 0 and 4 Em can reach 1000 to 2000, so the volume of the wire mesh separator is small. In addition, due to the small surface clearance of the screen, small Sum mist particles can be removed, the separation efficiency can reach more than 98%, and the resistance loss is not large. However, when the concentration of water and oil mist is high, the resistance will increase due to the pores being blocked by the mist.

Thermally conductive plastic: The thermally conductive filler is used to uniformly fill the polymer matrix material to improve its thermal conductivity. The thermal conductivity is mainly measured by the thermal conductivity (unit: W / m.k).

Thermally conductive plastics are divided into two categories: thermally conductive plastics and thermally insulating plastics. The main components of thermally conductive plastics include matrix materials and fillers. Matrix materials include PPS, PA6 / PA66, LCP, TPE, PC, PP, PPA, PEEK, etc .; fillers include AlN, SiC, Al2O3, graphite, fibrous high thermal conductivity carbon powder, scaly high thermal conductivity carbon powder, and the like.

Aluminum nitride has a very high thermal conductivity, but it is expensive, usually more than 1,000 yuan per kilogram. Although aluminum nitride can be used to achieve high thermal conductivity, the viscosity of the system rises sharply, limiting the application of the product. In addition, aluminum nitride will undergo hydrolysis reaction with water after absorbing moisture. AlN + 3H2O = Al (OH) 3 + NH3. The hydrolysis of Al (OH) 3 will interrupt the heat conduction path and affect the phonon transmission. After the finished product, the thermal conductivity is low. The surface treatment and coating of AlN with a silane coupling agent can effectively prevent the hydrolysis of aluminum nitride. The surface treatment technology of Japanese aluminum nitride manufacturers is at the leading level in the industry and is widely praised by engineers.

Although beryllium oxide has high thermal conductivity, its practical application in thermally conductive materials is greatly limited due to its high toxicity.

Boron nitride has very high thermal conductivity and stable properties. The price varies greatly depending on the purity of the product, ranging from a few hundred yuan to thousands of yuan per kilogram. Although the use of boron nitride alone can achieve high thermal conductivity, similar to aluminum nitride, the viscosity of the system increases significantly after a large amount of filling, which severely limits the application of the product. Some foreign manufacturers produce spherical boron nitride. The product has large particle size, small specific surface area, high filling rate, and is not easy to increase viscosity, but the price is extremely high.

Magnesium oxide is cheap, but it is easy to absorb moisture in the air, and it can not be filled in large amounts.

Zinc oxide, advantages: good particle size and uniformity, suitable for the production of thermal grease. Disadvantages: low thermal conductivity, not suitable for the production of high thermal conductivity products; light weight, strong viscosity increase, not suitable for potting.

Silicon oxide, crystalline silicon fine powder is suitable for bulk filling, reducing costs. However, its thermal conductivity is low and it is not suitable for producing high thermal conductivity products.

Alumina: Compared with other thermal conductive fillers, the thermal conductivity of Al2O3 is not the highest, but its lower price, wider source, and larger filling capacity are widely used as fillers for thermally conductive plastics, thermally conductive silicones, thermally conductive adhesives, and thermally conductive coatings. Al2O3 is usually used alone or mixed with other fillers. Currently available α-phase alumina thermally conductive powders in the market are mainly acicular, cylindrical, spherical, and spherical.

Filler selection

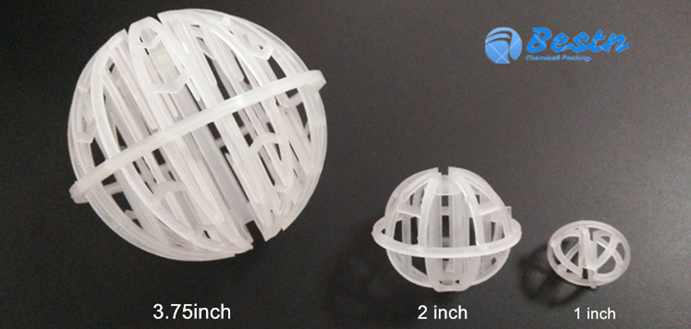

A 60-ton converter turbid ring water in a steelmaking plant contains a lot of dust, causing the internal packing of the cooling tower to be easily clogged, affecting the flow rate and cooling effect, and causing the packing to be replaced every two years. The cost of a single tower is about 40,000 yuan. In response to this problem, the relevant departments of the steel making plant communicated with the manufacturer when the two cooling tower fillers were replaced last time and decided to replace the fillers with new fillers suitable for turbid ring water cooling according to the water quality. This kind of packing guarantees the cooling effect, and the service life can be extended to more than 4 years, which greatly reduces the equipment maintenance and operation costs.

There are many types of fillers. Selecting suitable fillers for different application scenarios can greatly extend the replacement cycle of fillers, which can reduce production costs.

Company News

+

GENERAL ENQUIRY

Simply fill in the form below and we'll be in contact with you in 8 hours

Wechat

Wechat Skype

Skype Trade

Trade